Linen Fibres

At this point it might be of advantage to examine briefly the construction of the flax fibre and also in a lesser degree, the other fibres used in the production of the various fabrics sold in, what has come to be called, the Linen Department. This includes cotton, silk and wool, which are natural fibres, and also rayon, which is an artificially produced filament.

This is in no sense to be considered as “a battle Of the fibres,” as one, on account of its physical and chemical properties, will be suitable for one purpose and one for another.

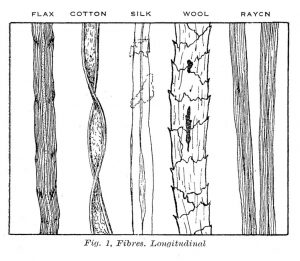

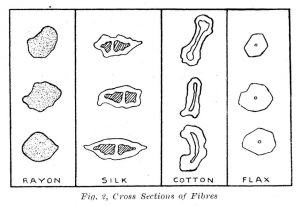

The chemical basis of cotton, flax and rayon is cellulose, but it is only necessary to look at the illustrations to see how materially each differs from the other in physical structure. (All illustrations in Parts Six and Seven are magnified from 500 to 3,000 times).

Of the fabrics made from these fibres, those which come closest to one another are linen and cotton, and the position of cotton, of course, goes without saying.

For several reasons cotton fabrics are cheaper to produce than are linen fabrics, and a very much larger volume of cotton is consequently consumed. On the other hand, linen for certain purposes is better adapted, and it becomes a question of whether for such purposes the superiority, desirability and better appearance of linen outweigh the difference in price. Some comparisons between cotton and linen will therefore be made.

Books are written on each Of these fibres, so in these brief descriptions only those points will be dealt with which are of interest in selling.

Flax and Cotton Fibre

Flax (linum usitatissimum) is a vegetable fibre of the bast species. Bast fibres consist of a large number of tiny cells compacted together to form a single fibre. Cotton fibre (gossypium) is a seed hair consisting of one single cell.

Flax fibres are from 12 to 24 inches in length, cylindrical in shape, straight, smooth and semi-transparent. Cotton fibres are from 1 to 2 inches in length, shaped like a ribbon with corded edges, hollow. and convoluted or twisted. (Illustration No.1).

It is the twist in the cotton fibre that gives it its spinning quality, as without these twists. the individual fibres would not catch on one another, and being so short, would slip apart.

Flax gets its cling, or spinning quality, partly from the length of the fibre, and also because-while keeping quite smooth-it has swellings, called “nodes.,” at intervals· throughout its length.

Lustre is caused by the refraction of light, and flax, because of its smoothness and transparency, has a beautiful, natural lustre not excelled by any of the vegetable fibres.

Looking at the cross sections (No.2), flax is a comparatively solid fibre with a minute channel down the centre. Cotton is a hollow fibre and in its cross section resembles a hosepipe squeezed flat. It is because it is a hollow fibre that cotton fabrics are so much lighter than comparable linen fabrics.

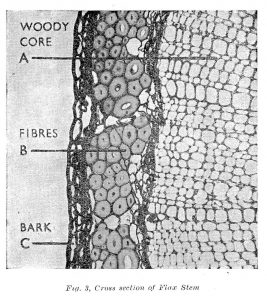

Illustration No.3 is part of the cross section of a flax “stem,” showing the position of the fibres; the complete circle of the stem must be imagined. “A” is the woody core. “B” is the fibre, and “C” is the outer skin, or bark. These are held together by the pectin gum referred to under “Retting.”

The particular colouring matter which makes linen so much more difficult to bleach than cotton, comes from small splinters off the woody core, known as sprit, which, together with the outer bark, get spun into the yarn.

The colouring in the bark is chlorophyl, which is the green in grass and in all plant life. It is yellowish on ripening, and in the retting process it turns to a brown which is fast and difficult to remove.

The actual fibre itself, is, like cotton, an ivory white, and with the sprit and bark removed, would be almost as easy to bleach as cotton. Cotton being a seed hair comes clean in ginning and, therefore, in bleaching does not have extraneous matter like sprit or bark, to contend with .

Ginning is the process whereby the cotton seeds are separated from the fibre.

Fibril Sub-Division

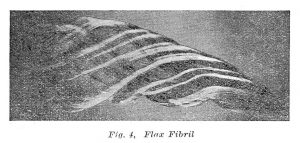

The ends of the individual flax fibres can be clearly seen in illustration No.3. These fibres each consist of a group of “fibrils.”

Illustration No. 4 shows a single flax fibre broken down into its “fibril” sub-division. This is a very interesting mico-photograph. It was taken in polarized light, as the fibrils are so minute the microscope could not pick them up under ordinary light.

It is also interesting from another point of view for it explains the well-known property of “rapid absorption of moisture” by linen. If you place a fine glass tube into a tumbler of water you will find that the water will rise in the tube appreciably higher than the surface of the water in the tumbler. The scientific name for this is “capillary attraction” and it is the capillary attraction set up between these minute fibrils that absorbs moisture so quickly.

While cotton can slowly absorb as much water as linen, and wool can absorb more than either, they do not absorb it so quickly. Linen dries by absorption whereas cotton dries more by surface attraction; that is the reason why cotton towels are generally made in a terry-looped weave, in order to afford a larger drying surface. Linen not only takes up moisture more rapidly, but it also (by evaporation) gives it off again more rapidly than do other textiles. This is an important recommendation for the linen sheet in connection with the “Hygienic Bed,” which will be referred to later.